Recent News

Schmidt On Facebook

Departments

Versatile and easy-to-use. These 6 cutter sets are designed to perform the 3 functions shown. Our standard sets cut 1/4" wide x 3/8" deep tongue and groove. Our common minor diameter requires NO fence adjustment when changing from cope to pattern cuts (3/8" tongue only).

Standard sets cut 1/4" wide x 3/8" deep tongue and

groove. For optional tongue and groove cutters and eased edge option, see Center Groover Sets and Optional Eased Edge Sets.

Profile Cutters Not Included. At time of purchase, you

may substitute the following tongue & groove cutters for the standard tongue & groove cutters in your cope & pattern set, at no additional charge. If you choose an optional center groover set, you will be unable to do the tongue & groove option

Standard sets cut 1/4" x

5/8" or 1/2" x 5/8" deep

tongue and groove. Mini-

Pro is not to be used on

1/2" spindle.

These 8 piece cutter sets

are built to cut both

1-3/8" passage doors and

1-3/4" entry doors simply

by changing the center

cutters.

Freeborn raised panel cutters

are manufactured with

15" SHEAR to produce

optimum cuts both with

and across the grain.

Counterclockwise rotation

with wood fed face up.

Manufactured with 15° SHEAR to produce optimum

cuts both with and across the grain.

Counterclockwise rotation with wood fed face up.

These raised panel cutters cut a 1-3/8" reveal plus a

3/8" long tongue.Reduce production time by adding an opposite rotation cutter to those above, and produce double sided raised panels in a single pass.

Freeborn raised panel cutters

are manufactured with

15º SHEAR to produce

optimum cuts both with

and across the grain.

Counterclockwise rotation

with wood fed face up.

Whether

it is a 30º back bevel,

fingerpull, 3/8” offset, or

flush overlay door, we

offer a wide selection

to choose from.

Counterclockwise

rotation with wood

fed face up.

For more profiles go

to Door Edge Details

page.

Whether

it is a 30º back bevel,

fingerpull, 3/8” offset, or

flush overlay door, we

offer a wide selection

to choose from.

Counterclockwise

rotation with wood

fed face up.

For more profiles go

to Door Edge Details

page.

Manufactured with

15º SHEAR to produce

optimum cuts both with

and across grain.

Counterclockwise rotation

with wood fed face up.

Any top cutter is designed

to nest and run with any

bottom cutter.

Run drawer front face

up in horizontal position

over the top of the cutter.

Drawer sides are run on

end in a vertical position

against the shaper fence.

Made to cut up to 3/4”

drawer sides.

Counterclockwise

rotation only.

Counterclockwise

rotation with wood face

down. When running

counterclockwise, cove cut

is made by lowering shaper

spindle to cut with the top

half of the cutter. Bead cut

is made by raising shaper

spindle to cut with the

bottom half of the cutter.

The V-Paneling set consists

of 5 cutters and 1 spacer to

perform these 4 functions.

Counterclockwise rotation

with wood fed face down.

The flooring set consists

of 6 cutters and 1 spacer

to perform 5

functions.

Cut provides a loose

fit (.030) for wood

expansion. Set up

instructions included.

Counterclockwise

rotation with wood fed

face down.

This set includes 5

cutters to perform the

cut as shown.

Counterclockwise

rotation with wood fed

face down. Up to 1”

material.

After machining two

pieces of wood, one piece

may be inverted and

plugged into its mate,

forming a matched joint.

Counterclockwise rotation with wood fed face up.

Straight Top Groovers are

ideal for cutting grooves,

rabbets, and for flush

trimming.

Larger PRO-LINE Cutters

exceed the standard 4”

diameter. Counterclockwise

rotation with wood fed

face down.

These window sash profiles

are common in many older

homes. They are made to

cut stock up to 1-3/4”.

Counterclockwise rotation

with wood fed face down.

Counterclockwise rotation

only. Mini-Pro is made to

run only on 3/4” spindle.

Part B is run flat in

horizontal position on

shaper table.

Part A is run in a vertical

position against the shaper

fence (see diagram).

Counterclockwise rotation

only. Mini-Pro is made to

run only on 3/4” spindle.

Material to 1-1/8”.

Part A and B are both run

flat in horizontal position

on shaper table. Part B is

run again on table saw to

cut groove (see diagram).

Each set includes 2 cutters and 2 spacers to cut 3/4”, 1”, 1-1/4” and 1-1/2” material.

Insert tooling with Freeborn quality, designed for accuracy and ease of use.

Our insert tooling features the following benefits:

• Common minor diameters and verticle profile centering.

With these two features you do not need to adjust the spindle height or fence position when switching from cope to

pattern cuts.

• Easy indexing when replacing tips.

Using a locating button on all sets, and a locking gib system for the cope and pattern sets and detail sets, changing

tips is a quick and accurate process.

• Cope and Pattern bodies will accept both square and eased edge tips

• Dedicated bodies for each profile ensure maximum safety and accuracy.

Ball Bearing Rub Collars • Rub Spacers for Cope and Pattern • T-Bushings • Spacers and Shims

Minicart

Our Products

- Custom Tools

- Shaper Cutters

- Accessories

- Beveled Edge Shaper Steel Bars

- Thin Knives for Planer & Jointers

- Tersa, Terminus, & Centrolock Knives

- SCHure-Lock Carbide Knife System

- Corrugated, Williams & Hussey Knife Stock

- Grinding Room Supplies

- Saw Blades

- Profile Knives

- Cutter Heads

- Rosettes

- Innovators

- Hollow Mortising Chisels & Bits

- Insert Heads & Cutters

- Router Tooling & Boring Bits

- CNC Router Tools

- Woodworking Machines, Tools & Jigs

- Powermatic Tenoner Heads

- FREEBORN TOOLS

- Dispozablade

- Groovers

- Window Sash Cutters

- Standard Carbide Tipped Shaper Cutters

- Flooring Tooling

- Shaper Cutters for Cabinet Doors

- Shaper Cutters for Entry Doors

- Corrugated Knife Cutter Heads for Shapers

- Carbide Tipped Fence Post Cutters

- Ball Bearing Rub Collars

- Color Coded Plastic Shims

- Spacer Sets

- Bushings

- Sprayway

- Space Balls

- Diamond Honing Cones

- Diamond Sharpening Stones

- Moulder Bed Lube

- Planer and Jointer Jigs

- Spindles

- Feed Rollers for Williams and Hussey

- Planer & Jointer Knife Sets

- Planer & Jointer Thin Knife Bars

- Smooth Back Planer & Jointer Knife Bars

- Planer & Jointer Accessories

- Tersa Replacement Knives

- Centrolock Replacement Knives

- Terminus Replacement Knives

- Tersa & Terminus Heads

- Corrugated Back 25" Steel Bars

- 25" Steel Filler Bars

- Williams & Hussey 25" Steel Bars

- Williams & Hussey Straight Knives for Profiling

- Carbide or S-Alloy Tipped Corrugated Back Knives

- Grinding Wheels

- Ceramic Grinding Wheels: For M2 High Speed Steel

- SCHure-Lock Carbide Knife System Grinding Wheels

- Grinding Coolant

- Template Material

- Diamond Dressers

- Tracing Pins

- Low Noise, Laster Cut Saw Blades

- Panel Saw Blades

- Scoring Saw Blades

- Miter & Chop Saw Blades

- Cut Off & Trim Saw Blades

- Rip Saws

- Dado Sets

- Glue Line Rip Blades

- Double Face Laminate Saws

- Combination Saws

- Solid Surface Saw Blades

- The Junior Line

- Standard Moulder Heads

- 1-1/4" Bore Cutter Heads

- Williams & Hussey Cutter Heads

- Standard Coping Discs

- HSK Heads

- Multiprofile Rosette Cutters

- Standard Profile Knives for Rosette Holders

- Blank Knives for Rosette Hodlers

- Powermatic Tenoner Tooling

- Profiling Heads

- Tenon Heads

- Rebating Heads

- Stackable Surfacing Heads

- Adjustable Groovers

- Adjustable Angle Cutter

- Dedicated Insert & Flooring Cutters

- Solid Carbide Indexible Inserts

- Solid Carbide Profile Inserts

- Panel Raising Insert Cutters

- Stile & Rail Insert Cutters

- Solid Carbide CNC Bits

- Spoil Board Cutters

- CNC Tool Holders & Arbors

- Collets & Nuts

- Corrugated Back Router Head & Knives

- Diamond Tipped Router Bits

- Cope & Pattern (6 cutter sets)

- Double Sided Cope & Pattern (6 cutter sets)

- Center Groover Sets (2 piece sets)

- Double Sided Cope & Pattern (8 cutter sets)

- Optional Glass Panel Groovers (2 cutter sets)

- Raised Panel Shaper Cutters (3/4" material)

- Raised Panel Shaper Cutters (1/2" material)

- Raised Panel Shaper Cutters (5/8" material)

- Back Cutters - Raised Panel (3/4" material)

- Raised Panel Tongue Trimmer

- Door Edge Detail Shaper Cutters

- Door Edge Detail Bevel Cutters

- Bead Cutters

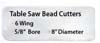

- Table Saw Bead Cutters

- Door Edge Details (32mm hinge system)

- Drawer Lock Cutter

- Matched Drop Leaf

- Reversible Glue Joint

- V-Paneling Shaper Cutter Set (3/4" to 1" material)

- 7-Piece Flooring Set (3/4" to 1" material)

- 5-Piece Flooring Set with Nail Slot

- 8-Piece Flooring / V-Paneling Set

- Quater Cove Convex Cutters

- Reversible Pattern Detail

- Straight Top Groovers

- Half Round Convex Shaper Cutters

- Half Round Concave Shaper Cutters

- Corner Rounding Shaper Cutters

- Window Sash Cutter Set (4 cutter set)

- Double Tongue & Groove Lock Mitre Cutter

- Single Tongue & Groove Lock Mitre Cutter (3 cutter set)

- 1-Piece Double Easing Cutters

- 4-Piece Expandable Double Easing Set

- Extended Quater Rounds

- Freeborn Insert Tooling

- Freeborn Accessories

- Freeborn Hand Rail Sets

- Freeborn Window Sill Cutters

2.jpg)